The Cube® is the ultimate destemming and sorting tool available today. Its smart design effortlessly adapts to different setups and needs.

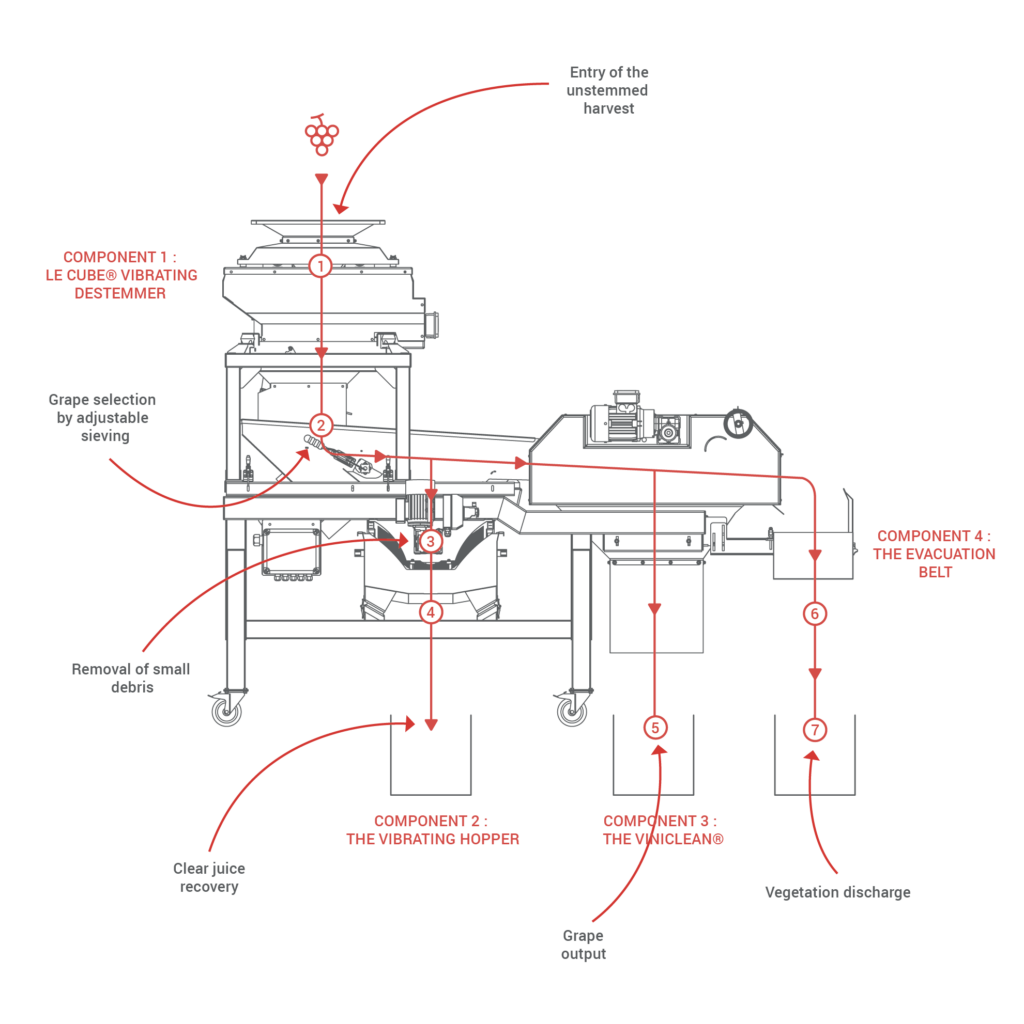

Featuring destemming fingers, it creates a vertical vibrating chute that clusters gently pass through. These clusters are guided by discs with flexible fingers. By using precise vibration, the berries release and gently fall along with the stems onto the vibrating hopper, which has an adjustable spacing grid.

The Cube® easily works with various feeding methods, including bins, screw conveyors, vibrating bins or conveyors, belts, vibrating sorting tables, conveyor belts, crates, and both manual and mechanical harvesting setups. It’s versatile for both destemming and sorting, or just sorting.

• Berries fall naturally using gravity while stems are guided downward by gentle discs

• The Cube offers precise adjustment suitable for all grape types

• The texture and flexible material of our sorting rollers ensure a strong hold on the plant without damaging the fruit

• The design offers clear visibility across the whole work area

• Complete cleaning in just 20 minutes

• Simple to access and adjust: a mechanical machine free of electronics

• A mobile destemmer with wheels

• Manual harvest throughput: 9 metric tonnes per hour; mechanical harvest throughput: 15 metric tonnes per hour

• Straightforward mechanics reduce breakdown risks

• Compact size for easy integration into the production line

• Les baies détachées descendent naturellement par gravité et les rafles sont entrainées vers le bas par des disques souples.

• La Cube permet un calibrage précis et adapté à tout type de cépage

• Les reliefs et la matière souple de nos rouleaux trieurs permettent une accroche optimale du végétal sans trituration du fruit grâce aux reliefs et à la matière souple de nos rouleaux trieurs.

• Une fabrication épurée permettant une visibilité totale sur l’ensemble de la zone de travail

• Un nettoyage complet en 15 min

• Simple d’accès et rapide à régler : une machine mécanique et pas électronique

• Un égreneur mobile sur roues

• Débit horaire de 9 T/H

• Une mécanique simple limitant les risques de pannes

• Un encombrement limité qui permet une meilleure intégration à la ligne de production

Manual harvesting rate

(according to grape variety and ripeness)

9 tons per hour

Mechanical harvesting rate

(according to grape variety and ripeness)

15 tons per hour

Absorbed electrical power

3.2 kw

Electrical supply

3 P+T

Electrical voltage

380 V

Minimum height

1 800 mm

Length

2 730 mm

Weight

650 kg

Débit en vendange manuelle

(selon cépage et maturité)

9 tonnes par heure

Débit en vendange mécanique

(selon cépage et maturité)

15 tonnes par heure

Puissance électrique absorbée

3.2 kw

Alimentation électrique

3 P+T

Tension électrique

380 V

Hauteur minimale

1 800 mm

Longueur

2 730 mm

Poids

650 kg

NEED INFORMATION OR A QUOTE? CONTACT US

ZAC du Castellas

599, Avenue du Col de Chèvre

11100 Montredon-des-Corbières

Tel. +33 (0)4 68 41 50 30

French Manufacturer

Connect with Us on Social Media:

© 2022 Les Frères Patacq – Legal Notice – Privcacy – Crafted by Créera